Spectro Alloys plans first-of-its-kind, $71 million recycling expansion at Rosemount facility

/State-of-the-art equipment will allow Spectro to produce valuable recycled products from aluminum cans and other post-consumer materials

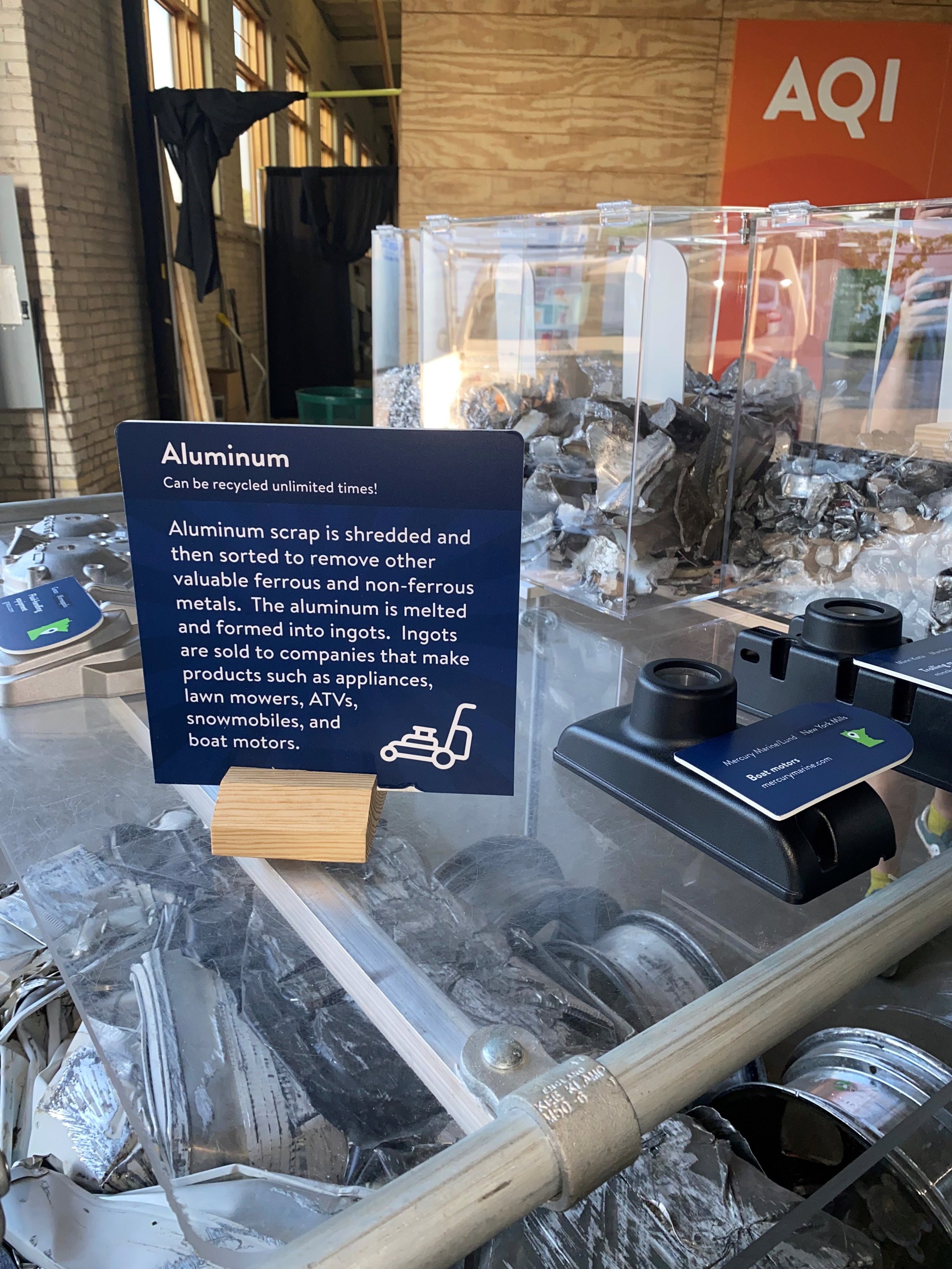

Rosemount, Minn. – September 7, 2023 – Spectro Alloys today announced a $71 million expansion to add new aluminum recycling equipment to its Rosemount campus. The investment will allow the leading Midwest-based aluminum recycler to expand its capabilities to sort and melt post-consumer scrap aluminum and cast it into various sheet and billet alloys. This expansion is in response to the need for improved recycling rates in Minnesota, and a growing market for recycled aluminum sheet and extrusion driven by consumer demand for sustainable products, green building standards, a stable domestic supply chain and cost savings associated with recycled material. Spectro Alloys will break ground on the project in 2024 and be operational in 2025.

To produce recycled billet and sheet ingot, Spectro Alloys is expanding its Rosemount campus to approximately 42 acres and will build a new 90,000-square-foot building along Highway 55. The first phase of the project will result in up to 120 million pounds per year of additional recycling capacity and create up to 50 new full-time jobs. Spectro Alloys is celebrating its 50th anniversary this year.

“As we celebrate 50 years of responsible aluminum recycling this month, we’re looking toward the future and the opportunity to improve recycling in Minnesota,” said Luke Palen, Spectro Alloys President.

Aluminum billet is used as raw material for extruders, who turn it into products like railings, window and door trim, and structural components for cars, boats, airplanes, trailers, docks, and more. Spectro will also recycle used beverage containers and other end of life aluminum products to produce sheet ingot – high purity slabs of aluminum weighing up to 60,000 pounds each – a feedstock for rolling mills.

In Minnesota, only 45% of aluminum beverage containers are currently being recycled, according to the Minnesota Pollution Control Agency. Spectro’s investment will promote more recycling by unlocking greater value through reuse while providing large direct environmental benefits. Spectro’s recycling process uses 95% less energy and releases 95% less CO2 than new aluminum production. With this expansion, aluminum recycling at Spectro Alloys will save enough energy to power every home in Minneapolis and St. Paul combined.

“This investment isn’t just about adding jobs and producing more, it’s about helping Minnesota as a whole become better at recycling by creating an extremely valuable type of aluminum that manufacturers need,” Palen said. “It is about closing the loop for locally sourced materials – ensuring the value in aluminum products we use every day supports responsible recycling of aluminum right here in Minnesota.”

The facility will include industry-leading automation and state-of-the-art equipment for sorting, melting, casting, and homogenizing aluminum scrap, and the best available technology for pollution control.

The billet project is the latest of several investments at Spectro Alloys. The company recently debuted a new 70,000-square-foot distribution center for shipping and processing finished products, air filtration and pollution control system upgrades, and a new business office and internal facilities for its team of 140 employees.